Loadcell WB, RTN, RTB, DWB, VBB, VEB Schenck Process

Load cell hay còn được gọi là cảm biến trọng lượng, nó được dùng để chuyển đổi lực mô-men xoắn hoặc trọng lượng thành tín hiệu điện.

Load cell thường được dùng trong các loại cân bàn, cân băng tải định lượng, cân silo, cân thép tấm, cân thép cuộn, cân xe...

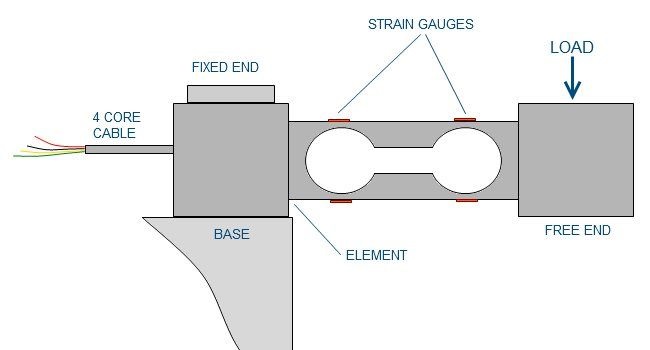

Loadcell được cấu tạo gồm phần thân loadcell và các Strain gauges

Khi có lực tác động lên loadcell, thân loadcell sẽ bị nén vào hoặc giản ra, từ đó các Strain gauges được dán trên thân loadcell sẽ bị thay đổi chiều dài làm cho giá trị điện trở thay đổi, tín hiệu điện trở này sẽ được kết nối với bộ cấp nguồn và bộ chuyển đổi tín hiệu để cho ra giá trị đo.

Tính năng chính :

Ứng dụng:

Nguyên lý hoạt động

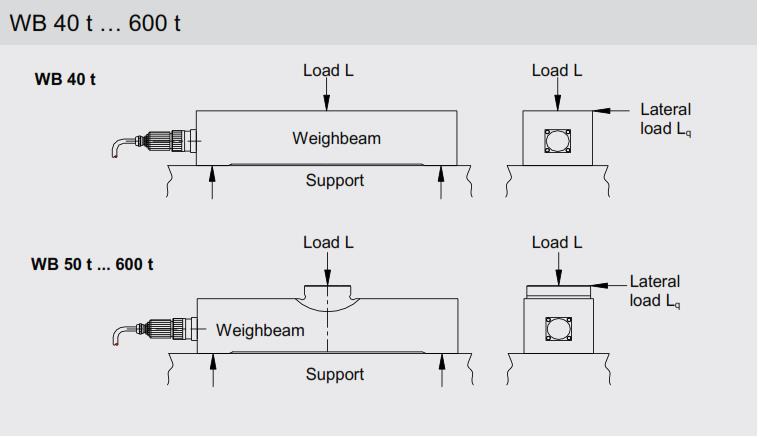

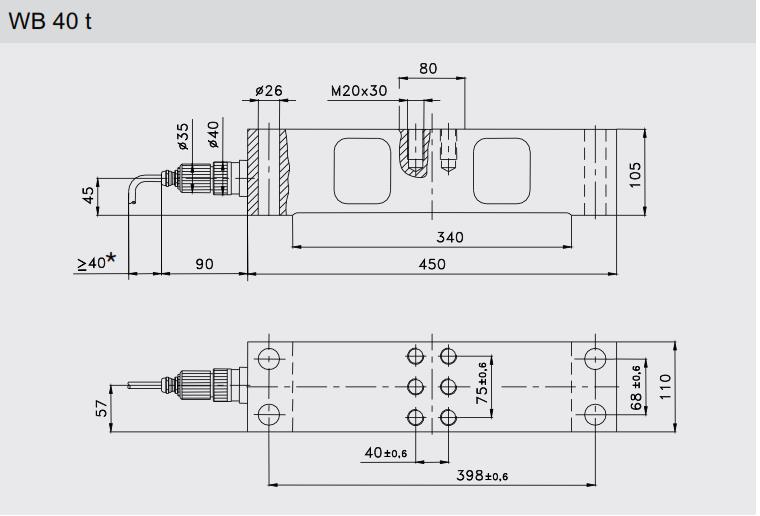

Kích thước lắp đặt:

Thông số kỹ thuật :

|

|

WB 40 t |

WB 50 t |

WB 100 t |

WB 150 t |

WB 200 t |

WB 600 t |

|

Dãi đo |

40t |

50t |

100t |

150t |

200t |

600t |

|

Tải phá hủy (with Lq = 0.15 x Ld) |

160t |

200t |

350t |

480t |

600t |

1200t |

|

Độ chính xác |

±0.05 % |

|

||||

|

Điện trở đầu vào |

694 Ω ±8 Ω |

|

||||

|

Điện trợ đầu rra |

700 Ω ±4 Ω |

|

||||

|

Nguồn cấp |

10V |

|

||||

|

Nguồn cấp Max |

36V |

|

||||

Order number:

|

Design |

Order number with straight plug outlet |

Order number with lateral plug outlet on the right |

|

WB 40 t |

V711375.B03 |

V758596.B01 |

|

WB 50 t |

V711375.B13 |

V758596.B11 |

|

WB 100 t |

V711375.B23 |

V758596.B21 |

|

WB 150 t |

V711375.B33 |

V758596.B31 |

|

WB 200 t |

V711375.B43 |

V758596.B41 |

|

WB 600 t |

V711375.B53 |

V758596.B51 |

|

Spare part: Connecting cable 15 m with plug connection |

V090162.B01 |

|

Tính năng chính :

Tiêu chuẩn phòng chống cháy nổ :

Thông số kỹ thuật:

|

Dãi đo (Emax) |

1t-470t |

1t-100t |

|

|

Độ chính xác |

0.05 |

C3 |

C5 / C4 Mi 7.5 |

|

Độ nhạy (Cn) |

2.85 mV/V ±2.85 µV/V |

||

|

Điện trở đầu ra |

4010 Ω±2Ω |

4010 Ω±0.5Ω |

|

|

Điện trở đầu vào |

4450Ω±100Ω |

||

|

Nhiệt độ môi trường |

-10 °C … +40 °C |

||

|

Nhiệt độ customized |

-40 °C … +80 °C, Option to +110 °C *) -30 °C … +70 °C |

||

|

Dây Cáp |

TPE (grey) Ø 6.5 mm, silicone and halogen free, -30 °C to +150 °C, Length 5 m for RTN 1 t - 15 t and RTN 150 t - 470 t Length 15 m for RTN 22 t - 100 t |

||

|

Nguồn cấp max |

60V |

||

Order No:

|

Variants |

Accuracy class |

||

|

|

0.05 |

C3 |

C5 / C4 Mi 7.5 |

|

RTN 1 t |

D726173.04 |

D726173.02 |

D726173.10 |

|

RTN 2.2 t |

D726174.04 |

D726174.02 |

D726174.10 |

|

RTN 4.7 t |

D726175.04 |

D726175.02 |

D726175.10 |

|

RTN 10 t |

D726176.04 |

D726176.02 |

D726176.10 |

|

RTN 15 t |

D726177.04 |

D726177.02 |

D726177.10 |

|

RTN 22 t |

D724781.04 |

D724781.02 |

D724781.10 |

|

RTN 33 t |

D724754.04 |

D724754.02 |

D724754.10 |

|

RTN 47 t |

D724782.04 |

D724782.02 |

D724782.10 |

|

RTN 68 t |

D724783.04 |

D724783.02 |

D724783.10 |

|

RTN 100 t |

D724784.04 |

D724784.02 |

D724784.10 |

|

RTN 150 t |

D726178.04 |

D726178.02 |

|

|

RTN 220 t |

D726179.04 |

D726179.02 |

|

|

RTN 330 t |

D726180.04 |

D726180.02 |

|

|

RTN 470 t |

D726181.04 |

D726181.02 |

|

Options :

Phụ kiện dùng cho loadcell RTN

SENSiQ™ Secure Mount (SSM)

|

Variants |

Order Number |

|

0.25 t |

V041091.B01 |

|

0.50 t |

V041092.B01 |

|

1 … 2.2 t |

D 731186.01 |

|

4.7 t |

D 731186.02 |

|

10 … 22 t |

D 731353.01 |

|

33 t |

D 731415.01 |

|

47 t |

V654503.B01 |

|

68 t |

V654503.B11 |

|

100 t |

V654503.B21 |

|

150 t |

V654503.B31 |

|

220 t |

V654503.B41 |

|

330 t |

V654503.B51 |

|

470 t |

V654503.B61 |

SENSiQ™ Elastomer Mount (SEM)

|

Standard SEM |

SEM with silicone (VMQ) |

||||||

|

Model/Order numbers |

Model/Order numbers |

||||||

|

SEM 0.25 |

V041386.B01 |

SEM 33 |

D 725575.02 |

SEM 1/2.2 |

D 726185.11 |

SEM 100 |

D 725575.25 |

|

SEM 0.50 |

V041387.B01 |

SEM 47 |

D 725575.03 |

SEM 4.7 |

D 726185.12 |

SEM 150 |

D 726186.11 |

|

SEM 1 |

D 726185.01 |

SEM 68 |

D 725575.04 |

SEM 10 … 22 |

D 725575.20 |

SEM 220 |

D 726186.12 |

|

SEM 2.2 |

D 726185.01 |

SEM 100 |

D 725575.05 |

SEM 10 … 22 |

D 725575.21*) |

SEM 330 |

D 726186.13 |

|

SEM 4.7 |

D 726185.02 |

SEM 150 |

D 726186.01 |

SEM 33 |

D 725575.22 |

SEM 470 |

D 726186.14 |

|

SEM 10 … 22 |

D 725575.10 |

SEM 220 |

D 726186.02 |

SEM 47 |

D 725575.23 |

|

|

|

SEM 10 … 22 |

D 725575.11*) |

SEM 330 |

D 726186.03 |

SEM 68 |

D 725575.24 |

|

|

|

|

|

SEM 470 |

D 726186.04 |

|

|

|

|

SENSiQ™ Pendulum Mount (SPM)

|

Variants |

Order number without base plate |

Order number |

Variants |

Order number without base plate |

Order number |

|

SPM 1 t |

D 725565.16 |

D 725565.11 |

SPM 47t |

D 725565.08 |

D 725565.03 |

|

SPM 2.2 t |

D 725565.17 |

D 725565.12 |

SPM 68 t |

D 725565.09 |

D 725565.04 |

|

SPM 4.7 t |

D 725565.18 |

D 725565.13 |

SPM 100 t |

D 725565.10 |

D 725565.05 |

|

SPM 10 t |

D 725565.19 |

D 725565.14 |

SPM 150 t |

|

D 726616.01 |

|

SPM 15 t |

D 725565.20 |

D 725565.15 |

SPM 220 t |

|

D 726616.02 |

|

SPM 22 t |

D 725565.06 |

D 725565.01 |

SPM 300 t |

|

D 726616.03 |

|

SPM 33 t |

D 725565.07 |

D 725565.02 |

SPM 470t |

|

D 726616.04 |

Ứng dụng:

Ứng dụng:

Thông số kỹ thuật

|

|

DWB 11.5t |

DWB 15t |

DWB 25t |

|

Dãi đo |

11.5t |

15t |

25t |

|

Giới hạn đo |

23t |

26t |

35t |

|

Độ nhải |

0.90 mV/V |

1.16 mV/V |

1.40 mV/V L |

|

Nhiệt độ |

-15oC+80 oC |

||

|

Trọng luọng |

18kg |

18kg |

18kg |

|

Order Number |

|

|

Options |

||

|

Variants |

Order No |

|

|

Variants |

Order No |

|

DWB 11.5 t |

D 703 100.01 |

|

|

DWB 11.5 t HT |

D 703 100.04 |

|

DWB 15t |

D 703 100.02 |

|

|

DWB 25 t HT |

D 704 280.05 |

|

DWB 25 t |

D 704 280.03 |

|

|

|

|

Thông số kỹ thuật:

|

|

5Kg – 0.5t |

|||

|

Accuracy class |

|

|

|

|

|

Nominal characteristic value |

2 mV/V +20 µV/V;

-2 µV/V |

2 mV/V ±1 µV/V |

||

|

|

|

|

|

|

|

Zero signal return after loading (30 min) |

±0.049 % |

±0.016 % |

±0.012 % |

±0.008 % |

|

Input resistance |

|

|||

|

Output resistance |

|

|

||

|

Zero signal |

|

|||

|

Supply power |

|

|||

|

Temperature range |

-10 °C … +40 °C |

|||

|

Service temperature range Explosion-proof design |

-40 °C … +70 °C -30 °C … +70 °C |

|||

Order Code:

|

Variants Load Cells |

|

Ex-Variants Load Cells |

Order No. 2GD |

Order No. 2D/3G |

|

VBB 5 kg D1 |

D 725 417.01 |

|

|

|

|

VBB 10 kg D1 |

D 725 417.02 |

|

|

|

|

VBB 10 kg СЗ |

D 725 419.02 |

VBB 10 kg СЗ „Ex" |

D 725 419.32 |

D 725 419.42 |

|

VBB 20 kg D1 |

D 725 417.03 |

|

|

|

|

VBB 20 kg C3 |

D 725 419.03 |

VBB 20 kg C3 „Ex" |

D 725 419.33 |

D 725 419.43 |

|

VBB 50 kg D1 |

D 725 417.04 |

|

|

|

|

VBB 50 kg C3 |

D 725 419.04 |

VBB 50 kg C3 „Ex" |

D 725 419.34 |

D 725 419.44 |

|

VBB 0.1 t D1 |

D 725 409.01 |

VBB 0,1 t D1 „Ex" |

D 725 409.61 |

D 725 409.41 |

|

VBB 0.1 t C3 |

D 725 409.04 |

VBB 0,1 t C3 „Ex" |

D 725 409.64 |

D 725 409.44 |

|

VBB 0.1 t C4 |

D 726 370.01 |

VBB 0,1 t C4 „Ex" |

D 726 370.31 |

D 726 370.41 |

|

VBB 0.2 t D1 |

D 725 409.02 |

VBB 0,2 t D1 „Ex" |

D 725 409.62 |

D 725 409.42 |

|

VBB 0.2 t C3 |

D 725 409.05 |

VBB 0,2 t C3 „Ex" |

D 725 409.65 |

D 725 409.45 |

|

VBB 0.2 t C4 |

D 726 370.02 |

VBB 0,2 t C4 „Ex" |

D 726 370.32 |

D 726 370.42 |

|

VBB 0.2 t C6 |

D 726 370.04 |

VBB 0,2 t C6 „Ex" |

D 726 370.34 |

D 726 370.44 |

|

VBB 0.5 t D1 |

D 725 409.03 |

VBB 0,5 t D1 „Ex" |

D 725 409.63 |

D 725 409.43 |

|

VBB 0.5 t C3 |

D 725 409.06 |

VBB 0,5 t C3 „Ex" |

D 725 409.66 |

D 725 409.46 |

|

VBB 0.5 t C4 |

D 726 370.03 |

VBB 0,5 t C4 „Ex" |

D 726 370.33 |

D 726 370.43 |

|

Variants Elastomer Mounts |

Order No |

|

VEB 5 kg – 0.2 t |

D 725 408.01 |

|

VEB 0.5 t |

D 725 408.02 |

| No. | Brand | Specification |

| 1 | SCHENCK PROCESS | Loadcell Model: D726176.10 RTN 10t C5/C4mi7.5 |

| 2 | SCHENCK PROCESS | D725565.14 SENSiQ Pendulum Mount SPM 10t with base plate |

| 3 | SCHENCK PROCESS | D726176.02 Load cell RTN 10t C3 according to data sheet BV-D 2019 GB |

| 4 | SCHENCK PROCESS | V058895.B05 Load cell PWS 150kg 0,05% data sheet BV-D 2214GB |

| 5 | SCHENCK PROCESS | V088601.B01 DISOCONT Tersus HL VCU 20100 with software VWF 2017X |

| 6 | SCHENCK PROCESS | V064080.B01 DISOCONT TERSUS VHM 20100 Control Unit for cabinet mounting |

| 7 | SCHENCK PROCESS | System 1: single-idler belt scale 1 Belt Weigher MULTIBELT BEP 10 1 Speed Transducer FGA 20 RSLE 1 INTECONT® Tersus VEG 20650 with Belt Weigher software 1 Documentation BV-H 2590 AA on DVD |

| 8 | SCHENCK PROCESS | alternative to system 1: multi-idler belt scale 1 Belt Weigher MULTIBELT BMP 10 1 Speed Transducer FGA 20 RSLE 1 INTECONT® Tersus VEG 20650 with Belt Weigher software 1 Documentation BV-H 2590 AA on DVD |

| 9 | SCHENCK PROCESS | Optional: Item 3 1 Communication Modul PROFIBUS VPB 28020 |

| 10 | SCHENCK PROCESS | Optional: Item 4 1 Communication Modul PROFINET VPN 28020 |

| 11 | SCHENCK PROCESS | Optional: Item 5 1 CFC-module |

| 12 | SCHENCK PROCESS | Item 6 1 STEP7- and TIA-library |

| 13 | SCHENCK PROCESS | Optional: Item 7 1 EasyServe VPC 20150, incl. connecting cable |

| 14 | SCHENCK PROCESS | Optional: Item 8 1 Wall-mounted housing for INTECONT Tersus |

| 15 | SCHENCK PROCESS | Optional: Item 9 1 m Measuring cable 5 x 2 x 0.5 mm², screened |

| 16 | SCHENCK PROCESS | V063320.B01 DISOMAT OPUS VEG 20700 maxi panel mount unit |

| 17 | SCHENCK PROCESS | V003853.B11 DISOCONT system unit VSE 20100 with program VMD 20150 |

| 18 | SCHENCK PROCESS | V044393.B03 DISOCONT Memory card VSM 20102, for extended functions |

| 19 | SCHENCK PROCESS | V013257.B04 Weighbeam DWR 50 t with 15 meter cable and connector. Execution in accordance to data sheet BV-D 2183GB |

| 20 | SCHENCK PROCESS | V023643.B01 Connecting cable for DWR / WDI in accordance to Data Sheet BV-D 2183/2206GB length 15 m with plug connector |

| 21 | SCHENCK PROCESS | V090162.B01 Measuring cable SENSiQ plug 11-pole, length 15m with connector socket |

| 22 | SCHENCK PROCESS | Part No. V058895.B04 Load cell PWS 100kg 0,05% |

| 23 | SCHENCK PROCESS | V711375.B23 SENSiQ Weighbeam WB 100t, design according to data sheet BV-D 2453, with 15 m of cable and connecting plug |

| 24 | SCHENCK PROCESS | V023643.B01 Connecting cable for DWR / WDI in accordance to Data Sheet BV-D 2183/2206GB length 15 m with plug connector |

| 25 | SCHENCK PROCESS | Loadcell Model: D726176.10 RTN 10t C5/C4mi7.5 |

| 26 | SCHENCK PROCESS | D725565.14 SENSiQ Pendulum Mount SPM 10t with base plate |

| 27 | SCHENCK PROCESS | Part No. V058895.B04 Load cell PWS 100kg 0,05% |

| 28 | SCHENCK PROCESS | V555055.B03 SENSiQ Secure Mount-PLUS (SSM-PLUS) 22t SENSiQ SSM-PLUS including stopping unit, reinforced up to 40% of horizontal force and against lift up. --------------------------------CONSIST OF: 1x ELASTOMER MOUNT SEM 1x UPPER WELDING PLATE SEM 1x LOWER WELDING PLATE SEM 1x SENSiQ SSM-PLUS, steel parts 5x SHIM SSM-PLUS --------------------------------Design and manufacturing certified after DIN EN 1090-2 EXC 2 |

| 29 | SCHENCK PROCESS | V078510.B01 Operator panel VOP 28000 |

| 30 | SCHENCK PROCESS | V081004.B01 DISOBOX VME21041 Data acquisition unit for strain gauge load cells, 4 channels, with overvoltage protection |

| 31 | SCHENCK PROCESS | D724754.02 Load cell RTN 33t C3 standard with special cable length of 15 meters according to data sheet BV-D2019GB. |

| 32 | SCHENCK PROCESS | V058895.B04 Load cell PWS 100kg 0,05% data sheet BV-D 2214 |

| 33 | SCHENCK PROCESS | System 1: Multi Idler Belt Scale 1 Belt Weigher MULTIBELT® BMP 10 1 Speed Transducer FGA 20 RSLE 1 Documentation BV-H 2590 AA on DVD |

| 34 | SCHENCK PROCESS | Option INTECONT® Tersus VEG 20650 with Belt Weigher software |

| 35 | SCHENCK PROCESS | Option Communication Modul PROFIBUS VPB 28020 |

| 36 | SCHENCK PROCESS | Option CFC-module |

| 37 | SCHENCK PROCESS | Option STEP7- and TIA-library |

| 38 | SCHENCK PROCESS | Option EasyServe VPC 20150, incl. connecting cable |

| 39 | SCHENCK PROCESS | Option Wall-mounted housing for INTECONT Tersus |

| 40 | SCHENCK PROCESS | Option m Measuring cable 5 x 2 x 0.5 mm², screened |

| 41 | SCHENCK PROCESS | Mat No. V053953.B01 Cable junction box VKK 28004, for max. 4 load cells, polyester housing, spring terminals |

| 42 | SCHENCK PROCESS | Mat No. V053953.B01 Cable junction box VKK 28004, for max. 4 load cells, polyester housing, spring terminals |

| 43 | SCHENCK PROCESS | Mat No. V053953.B01 Cable junction box VKK 28004, for max. 4 load cells, polyester housing, spring terminals |

| 44 | SCHENCK PROCESS | V053953.B01 Cable junction box VKK 28004, for max. 4 load cells, polyester housing, spring terminals |

| 45 | SCHENCK PROCESS | V063320.B01 DISOMAT OPUS VEG 20700 maxi panel mount unit Note: Discontinued device series. Please do not use for new plants. Only serves for spare parts supply. |

| 46 | SCHENCK PROCESS | V535499.B01 Profinet I/O board VPN 28020 complete kit for DISOMAT Tersus, Satus, Opus VKG, DISOBOX plus, INTECONT Satus and INTECONT Opus VKG |

| 47 | SCHENCK PROCESS | D726174.04 Load cell RTN 2,2t 0,05% according to data sheet BV-D2019GB |

| 48 | SCHENCK PROCESS | D726185.01 SENSiQ Elastomer Mount SEM 1t/2,2t According to data sheet BV-D2044GB |

| 49 | SCHENCK PROCESS | Components for existing belt weigher 2pcs INTECONT® Tersus VEG 20650 with Belt Weigher software 2pcs Communication Modul PROFIBUS VPB 28020 1pcs CFC-module 2pcs Wall-mounted housing for INTECONT Tersus 2pcs Documentation BV-H 2590 AA on DVD 2pcs Speed Transducer FGA 20 RSLE |

| 50 | SCHENCK PROCESS | Optional 1pcs EasyServe VPC 20150, incl. connecting cable |

| 51 | SCHENCK PROCESS | D726176.10 Load Cell RTN 10t C5 / C4MI7,5 According to data sheet BV-D2019GB |

| 52 | SCHENCK PROCESS | D725565.14 SENSiQ Pendulum Mount SPM 10t with base plate Design according to data sheet BV-D 2025 GB |

| 53 | SCHENCK PROCESS | V058895.B04 Load cell PWS 100kg 0,05% data sheet BV-D 2214 |

| 54 | SCHENCK PROCESS | V058895.B04 Load cell PWS 100kg 0,05% data sheet BV-D 2214 |

| 55 | SCHENCK PROCESS | V058895.B04 Load cell PWS 100kg 0,05% data sheet BV-D 2214 |

| 56 | SCHENCK PROCESS | Components for existing belt weigher 2pcs INTECONT® Tersus VEG 20650 with Belt Weigher software 2pcs Communication Modul PROFIBUS VPB 28020 1pcs CFC-module 2pcs Wall-mounted housing for INTECONT Tersus 2pcs Documentation BV-H 2590 AA on DVD 2pcs Speed Transducer FGA 20 RSLE |

| 57 | SCHENCK PROCESS | V058895.B04 Load cell PWS 100kg 0,05% data sheet BV-D 2214 |

| 58 | SCHENCK PROCESS | W016747.B27 pc board 30001074 |

| 59 | SCHENCK PROCESS | D724754.02 Load cell RTN 33t C3 standard with special cable length of 15 meters According to data sheet BV-D2019GB |

| 60 | SCHENCK PROCESS | D725575.02 SENSiQ Elastomer Mount SEM 33t According to data sheet BV-D2044GB |

| 61 | SCHENCK PROCESS | V053953.B01 Cable junction box VKK 28004, for max. 4 load cells, polyester housing, spring terminals |

| 62 | SCHENCK PROCESS | D707200.01 Manual Measuring Eye DKI 206, German language |

| 63 | SCHENCK PROCESS | V096012.B01 DISOMAT Tersus ZEUS with printer and including 1 set of weigh slips Replacement for V054083.B01 |

| 64 | SCHENCK PROCESS | V040079.B01 Activating software road scale, program ZEUS in the DISOMAT OPUS |

| 65 | SCHENCK PROCESS | V054098.B01 Option card VEA 20451 for DISOMAT Tersus / INTECONT Tersus adds 2 analog output (-Xai) 2 analog input (-Xao) |

| 66 | SCHENCK PROCESS | V040080.B12 DISOMAT Opus ZEUS with legal-for-trade memory VMM 20407 Discontinued. Please do not use for new plants. Only serves for spare parts supply (Mat No. V040080.B12 replace for V040080.B02) |

| 67 | SCHENCK PROCESS | V054078.B01 Manual operating instructions ZEUS road weighbridge DISOMAT Tersus BV-H 2341 Note: The manual mentioned (D70727302) is for DISOMAT F and will not be sutiable to DISOMAT TERSUS. We offer you the manual BVH 2341 for DISOMAT TERSUS |

| 68 | SCHENCK PROCESS | V085231.B01 Load cell cable, screened 1 x 2 x 0,5mm2 + 2 x 2 x 0,25mm2 KS-Li2YYCY |

| 69 | SCHENCK PROCESS | Mat No. D724782.02 Load cell RTN 47t C3 According to data sheet BV-D2019GB |

| 70 | SCHENCK PROCESS | Mat No. V096000.B01 DISOMAT Tersus, panel mount unit VEG 20450, In accordance to data sheet BVD 2273 Consisting of: 1 measuring circuit VME 0450/ loaded software: VWW 20450 |

| 71 | SCHENCK PROCESS | Mat No. D724782.02 Load cell RTN 47t C3 According to data sheet BV-D2019GB |

| 72 | SCHENCK PROCESS | Mat No. V096000.B03 DISOMAT Tersus, panel mount unit VEG 20450, in accordance to data sheet BVD 2273 consisting of: 1 measuring circuit VME 0450, 1 Profibus-DP host controller board VPB 8020 loaded software: VWW 20450 |

| 73 | SCHENCK PROCESS | Bearing kit for paddle drive consisting of: 2x Pivot bearing Pos. 6.2 2x Grooved ball bearing Pos.6.3 2x Friction bearing LFI 1214-16 Pos.6.6 1x Friction bearing LFM 5055-50 Pos.6.5 4x Safety ring DIN 471 40x1,75 Pos.6.1 3x Flange bearing in front Pos.6.8 Mat No. V002131.B01 Weight: 1.1kg Pos. 6 |

| 74 | SCHENCK PROCESS | O-Ring, sealing, swivel box Mat No. V163489.B01 Pos. 15 |

| 75 | SCHENCK PROCESS | Radial Sealing 50x68x8 Svivel Box MechaTron MidRange Mat No. V163494.B01 Pos. 16 |

| 76 | SCHENCK PROCESS | Hopper PVC white MechaTron MidRange ConiFlex Mat No. V161914.B03 Weight: 7.257kg Pos. 1 |

| 77 | SCHENCK PROCESS | Clamp (V-Band) d = 483 mm, with T - Bolt latch. Mat No. V168297.B01 Pos. 11 |

| 78 | SCHENCK PROCESS | Downturn nozzle 44mm Bayonet MET M CF Mat No. F042166.01 Weight: 2.3kg Pos. 12 |

| 79 | SCHENCK PROCESS | Vertical Discharge Nozzle 76mm MechaTron MidRange ConiFlex Mat No. F042168.01 Weight: 4.5kg Pos. 12 |

| 80 | SCHENCK PROCESS | Protection cover Food d=168,3 Mat No. V093617.B08 Pos. 18 |

| 81 | SCHENCK PROCESS | Flexible connection DN150 silicone, suitable for pipe diameter 168,3 mm Mat No. V473116.B05 Pos. 17 |

| 82 | SCHENCK PROCESS | Universal clamping set >DN40-100, consisting of: 5 screw locks DN40 - 100 and 5 screw locks DN100 and 6 meter clamping strip suitable for flexible connection. Mat No. Z950430.03 Pos. 50 |

| 83 | SCHENCK PROCESS | Weighing module PWS 300 kg, stainless steel series M Mat No. V031607.B03 Weight: 8kg Pos. 2 |

| 84 | SCHENCK PROCESS | Silicone sealing profile 10 x 3 mm, self-adhesive Only available in rolls of 8,0 meter Mat No. 2422042 Pos. 10 |

| 85 | SCHENCK PROCESS | Tension ring CA0850/210-868-S-M8-DN850 Mat No. 4377310 Weight: 1.2kg Pos. 9 |

| 86 | SCHENCK PROCESS | Flexible connection 303mm x 80 silicone Mat No. E102702.67 Pos. 7 |

| 87 | SCHENCK PROCESS | Helix 76 x 76 MechaTron MidRange Nominal Diameter: 76mm; Pitch: 76mm Total Length: 637mm Mat No. V152921.B01 Weight: 2.7kg Pos. 3 |

| 88 | SCHENCK PROCESS | Helix 44 x 44 Nominal Diameter:44 mm; Pitch : 44 mm Total Length:637 mm MechaTron MidRange Mat No. V152249.B01 Pos. 3 |

| 89 | SCHENCK PROCESS | Drive shaft, gearbox side, without key, MechTron feeder Mat No. V019221.B04 Weight: 1.36kg Pos. 5.1 |

| 90 | SCHENCK PROCESS | Key DIN 6885 St60-2K 6 x 6 x 32 Mat No. V004115.B01 Pos. 5.2 |

| 91 | SCHENCK PROCESS | Shaft lock-down device 20mm Mat No. V017074.B01 Pos. 5.3 |

| 92 | SCHENCK PROCESS | Bearing housing standard, complete with seal cartridge and drive shaft. New design MET M CF Mat No. V040487.B01 Weight: 3.9kg Pos. 13 |

| 93 | SCHENCK PROCESS | Bearing housing standard without drive shaft MET M CF Mat No. V040488.B01 Weight: 2.3kg Pos. 13.3 |

| 94 | SCHENCK PROCESS | Seal cartridge including wear protection sleeve for MechaTron Mat No. V041255.B01 Pos. 13.1 |

| 95 | SCHENCK PROCESS | Hose clip DIN 3017 AS110-130A-W1 Mat No. 4374412 Pos. 13.2 |

| 96 | SCHENCK PROCESS | Carrier shaft (inch) complete, MET for MechaTron-Feeder Mat No. V034595.B01 Pos. 13.5 |

| 97 | SCHENCK PROCESS | Gearmotor IE2 - i = 15 - 0.75kW - 230/400V 50 Hz for single- and twin shaft feeders series M Mat No. V097232.B36 Weight: 15kg Pos. 4 |

| 98 | SCHENCK PROCESS | Gear motor agitation MET M CF, slow for food application Mat No. V061046.B50 Weight: 11kg Pos. 20 |

| 99 | SCHENCK PROCESS | DISOCONT Tersus HL, VCU 20100 with software VLW 20172 and analog output 0(4)-20 mA VAO 20100 also analog input 0(4)-20 mA VAI 20100 and fieldbus card PROFIBUS VPB 28020. Mat No. V089990.B77 Weight: 1.3kg |

| 100 | SCHENCK PROCESS | DISOCONT Tersus VCU 20100 HL with software VLW 2017X Mat No. V088600.B01 Weight: 1.15kg |

| 101 | SCHENCK PROCESS | PROFIBUS DP board VPB 28020 complete board including counterplugs for INTECONT Tersus, INTECONT Opus VEG, DISOCONT Tersus Mat No. V081901.B01 |

| 102 | SCHENCK PROCESS | DISOCONT TERSUS VAO 20100 Analog output 0-20mA / max. 11V Mat No. V078801.B01 |

| 103 | SCHENCK PROCESS | VAI 20100 - Analog Input modul 20mA/10V Mat No. V078800.B01 |

| 104 | SCHENCK PROCESS | Frequency converter J1000 without cooling element 0,75 kW (ND) / 400 VAC Mat No. V741164.B02 |

| 105 | SCHENCK PROCESS | EMC filter FS23639-5-07 for frequency converter base (underbody) version YEG power rating : 0,25 - 1,1 kW, 3*400V Mat No. V741165.B01 |

| 106 | SCHENCK PROCESS | Motor protection switch PKZM0-1,6 Mat No. 3724157 |

| 107 | SCHENCK PROCESS | Auxiliary switch VHi11-PKZM1 Mat No. 3724932 |

| 108 | SCHENCK PROCESS | CONTACTOR 3RT2016-1BB41, 400V/4kW/24V DC Mat No. V511833.B03 |

| 109 | SCHENCK PROCESS | Anti-interference link, diode LG-LCD 24-220V Mat No. E093458.03 |

| 110 | SCHENCK PROCESS | Protect switch TCP_1A Mat No. V662777.B01 |

| 111 | SCHENCK PROCESS | Operator Unit VHM 20110 with low sized housing Complete with connection cable 3m and Plug M12 - 8 pol (IP65) additional an adapter cable M12 to DISOCONT TERSUS X96 (IP20) Mat No. V134591.B01 Weight: 1.2kg |

| 112 | SCHENCK PROCESS | D726175.04 Load Cell RTN 4,7t 0,05% According to data sheet BV-D2019GB |

| 113 | SCHENCK PROCESS | V535499.B01 Profinet I/O board VPN 28020 complete kit for DISOMAT Tersus, Satus, Opus VKG, DISOBOX plus, INTECONT Satus and INTECONT Opus VKG |

| 114 | SCHENCK PROCESS | V063320.B01 DISOMAT OPUS VEG 20700 maxi panel mount unit Important Note: Discontinued device series. Please do not use for new plants. Only serves for spare parts supply. |

| 115 | SCHENCK PROCESS | V053953.B01 Cable junction box VKK 28004, for max. 4 load cells, polyester housing, spring terminals |

| 116 | SCHENCK PROCESS | D726185.02 SENSiQ Elastomer Mount SEM 4,7t According to data sheet BV-D2044GB |

| 117 | SCHENCK PROCESS | V096002.B01 DISOMAT Tersus, stainless steel unit VKG 20450 desktop mounting in accordance with spec sheet BV-D 2273 Consisting of: 1 measuring circuit VME 450 loaded software VWW 20450 |

| 118 | SCHENCK PROCESS | F020401.01 Belt tacho FGA 20 RSLE, design in zinc, with friction wheel, rocker and support |

| 119 | SCHENCK PROCESS | Mat No. V058895.B06 Load cell PWS 300kg 0,05% data sheet BV-D 2214GB |

| 120 | SCHENCK PROCESS | D726175.04 Load Cell RTN 4,7t 0,05% According to data sheet BV-D2019GB |

| 121 | SCHENCK PROCESS | V053953.B01 Cable junction box VKK 28004, for max. 4 load cells, polyester housing, spring terminals |

| 122 | SCHENCK PROCESS | D726185.02 SENSiQ Elastomer Mount SEM 4,7t According to data sheet BV-D2044GB |

| 123 | SCHENCK PROCESS | V064005.B01 DISOCONT Tersus VCU 20104 VCF 20171 Stock Retrofit Version. ( with standard parameter ) |

| 124 | SCHENCK PROCESS | V064080.B01 DISOCONT TERSUS VHM 20100 Control Unit for cabinet mounting 100% replacement of V064089.B01 |

| 125 | SCHENCK PROCESS | D724782.02 Load cell RTN 47t C3 According to data sheet BV-D2019GB |

| 126 | SCHENCK PROCESS | V058895.B04 Load cell PWS 100kg 0,05% data sheet BV-D 2214 |

| 127 | SCHENCK PROCESS | V058895.B04 Load cell PWS 100kg 0,05% data sheet BV-D 2214 |

| 128 | SCHENCK PROCESS | F020401.01 Belt tacho FGA 20 RSLE, design in zinc, with friction wheel, rocker and support |

| 129 | SCHENCK PROCESS | D726173.02 Load cell RTN 1t C3 According to data sheet BV-D2019GB |

| 130 | SCHENCK PROCESS | V058895.B04 Load cell PWS 100kg 0,05% data sheet BV-D 2214 |

| 131 | SCHENCK PROCESS | F217906.01 DISOCONT operator unit VLB 20100 in control cubicle housing, without power supply |

| 132 | SCHENCK PROCESS | F217906.01 DISOCONT operator unit VLB 20100 in control cubicle housing, without power supply |

| 133 | SCHENCK PROCESS | F217906.01 DISOCONT operator unit VLB 20100 in control cubicle housing, without power supply |

| 134 | SCHENCK PROCESS | V044393.B03 DISOCONT Memory card VSM 20102, for extended functions |

| 135 | SCHENCK PROCESS | F217906.01 DISOCONT operator unit VLB 20100 in control cubicle housing, without power supply |

| 136 | SCHENCK PROCESS | V044393.B03 DISOCONT Memory card VSM 20102, for extended functions |

| 137 | SCHENCK PROCESS | V003853.B11 DISOCONT system unit VSE 20100 with program VMD 20150 |

| 138 | SCHENCK PROCESS | V044393.B03 DISOCONT Memory card VSM 20102, for extended functions |

| 139 | SCHENCK PROCESS | D726176.02 Load cell RTN 10t C3 according to data sheet BV-D 2019 GB |

| 140 | SCHENCK PROCESS | D726175.04 Load Cell RTN 4,7t 0,05% According to data sheet BV-D2019GB |

| 141 | SCHENCK PROCESS | V535499.B01 Profinet I/O board VPN 28020 complete kit for DISOMAT Tersus, Satus, Opus VKG, DISOBOX plus, INTECONT Satus and INTECONT Opus VKG |

| 142 | SCHENCK PROCESS | V063320.B01 DISOMAT OPUS VEG 20700 maxi panel mount unit Discontinued device series. Please do not use for new plants. Only serves for spare parts supply. |

| 143 | SCHENCK PROCESS | V053953.B01 Cable junction box VKK 28004, for max. 4 load cells, polyester housing, spring terminals |

| 144 | SCHENCK PROCESS | D726185.02 SENSiQ Elastomer Mount SEM 4,7t According to data sheet BV-D2044GB |

| 145 | SCHENCK PROCESS | V064005.B01 DISOCONT Tersus VCU 20104 VCF 20171 Stock Retrofit Version. ( with standard parameter ) |

| 146 | SCHENCK PROCESS | V064080.B01 DISOCONT TERSUS VHM 20100 Control Unit for cabinet mounting 100% replacement of V064089.B01 |

| 147 | SCHENCK PROCESS | V082001.B01 INTECONT TERSUS VEG 20650 with software VWF 20650, for weight feeder |

| 148 | SCHENCK PROCESS | F217906.01 DISOCONT operator unit VLB 20100 in control cubicle housing, without power supply |

| 149 | SCHENCK PROCESS | D726174.04 Load cell RTN 2,2t 0,05% according to data sheet BV-D2019GB |

| 150 | SCHENCK PROCESS | D726185.01 SENSiQ Elastomer Mount SEM 1t/2,2t According to data sheet BV-D2044GB |

| 151 | SCHENCK PROCESS | V053953.B01 Cable junction box VKK 28004, for max. 4 load cells, polyester housing, spring terminals |

| 152 | SCHENCK PROCESS | V063320.B01 DISOMAT OPUS VEG 20700 maxi panel mount unit Note: Provide for Spare Part only. Do not use for new plant |

| 153 | SCHENCK PROCESS | V535499.B01 Profinet I/O board VPN 28020 complete kit for DISOMAT Tersus, Satus, Opus VKG, DISOBOX plus, INTECONT Satus and INTECONT Opus VKG |

| 154 | SCHENCK PROCESS | V058895.B06 Load cell PWS 300kg 0,05% data sheet BV-D 2214GB |

| 155 | SCHENCK PROCESS | D724781.10 Load cell RTN 22t C5 / C4MI7,5 According to data sheet BV-D2019GB |

| 156 | SCHENCK PROCESS | D731415.01 SENSiQ Secure Mount SSM 33t According data sheet BV-D 2083 GB Design and manufacturing certified after DIN EN 1090-2 EXC 2 |

| 157 | SCHENCK PROCESS | V064005.B01 DISOCONT Tersus VCU 20104 VCF 20171 Stock Retrofit Version. ( with standard parameter ) |

| 158 | SCHENCK PROCESS | V064080.B01 DISOCONT TERSUS VHM 20100 Control Unit for cabinet mounting |

| 159 | SCHENCK PROCESS | V084273.B01 DISOCONT Tersus VCU 20103 Tropes with Software VCF 20170 Stock Version MOQ=5pcs |

| 160 | SCHENCK PROCESS | V058895.B04 Load cell PWS 100kg 0,05% data sheet BV-D 2214 |

| 161 | SCHENCK PROCESS | D726173.02 Load cell RTN 1t C3 According to data sheet BV-D2019GB |

| 162 | SCHENCK PROCESS | V082002.B01 INTECONT Tersus VEG 20650 with software VBW 20650 for beltweighers |

| 163 | SCHENCK PROCESS | F020401.01 Belt tacho FGA 20 RSLE, design in zinc, with friction wheel, rocker and support. |

| 164 | SCHENCK PROCESS | V063320.B01 DISOMAT OPUS VEG 20700 maxi panel mount unit Note: Discontinued device series. Please do not use for new plants. Only serves for spare parts supply. |

| 165 | SCHENCK PROCESS | V535499.B01 Profinet I/O board VPN 28020 complete kit for DISOMAT Tersus, Satus, Opus VKG, DISOBOX plus, INTECONT Satus and INTECONT Opus VKG |

| 166 | SCHENCK PROCESS | V084273.B01 DISOCONT Tersus VCU 20103 Tropes with Software VCF 20170 Stock Version MOQ=5pcs |

| 167 | SCHENCK PROCESS | D726173.02 Load cell RTN 1t C3 According to data sheet BV-D2019GB |

| 168 | SCHENCK PROCESS | F020401.02 Belt tacho FGA 20-RSLE stainless steel with friction wheel, rocker and support. |

| 169 | SCHENCK PROCESS | V082002.B03 INTECONT Tersus VEG 20650 with software VBW 20650 for belt weighers with Option: PROFIBUS - interface |

| 170 | SCHENCK PROCESS | V003853.B11 DISOCONT system unit VSE 20100 with program VMD 20150 |

| 171 | SCHENCK PROCESS | V044393.B03 DISOCONT Memory card VSM 20102, for extended functions |

| 172 | SCHENCK PROCESS | V003853.B11 DISOCONT system unit VSE 20100 with program VMD 20150 |

| 173 | SCHENCK PROCESS | V044393.B03 DISOCONT Memory card VSM 20102, for extended functions |

| 174 | SCHENCK PROCESS | V003853.B11 DISOCONT system unit VSE 20100 with program VMD 20150 |

| 175 | SCHENCK PROCESS | V044393.B03 DISOCONT Memory card VSM 20102, for extended functions |

| 176 | SCHENCK PROCESS | F020401.01 Belt tacho FGA 20 RSLE, design in zinc, with friction wheel, rocker and support |

| 177 | SCHENCK PROCESS | V035374.B02 DISOCONT control unit in field housing VLB 20120-3D, for ATEX zone 22 |

| 178 | SCHENCK PROCESS | V082001.B01 INTECONT TERSUS VEG 20650 with software VWF 20650, for weight feeder |

| 179 | SCHENCK PROCESS | V058895.B04 Load cell PWS 100kg 0,05% data sheet BV-D 2214 |

| 180 | SCHENCK PROCESS | D726175.04 Load Cell RTN 4,7t 0,05% According to data sheet BV-D2019GB |

| 181 | SCHENCK PROCESS | D726185.02 SENSiQ Elastomer Mount SEM 4,7t According to data sheet BV-D2044GB |

| 182 | SCHENCK PROCESS | V058895.B04 Load cell PWS 100kg 0,05% data sheet BV-D 2214 |

| 183 | SCHENCK PROCESS | D726176.02 Load cell RTN 10t C3 according to data sheet BV-D 2019 GB |

| 184 | SCHENCK PROCESS | V064005.B01 DISOCONT Tersus VCU 20104 VCF 20171 Stock Retrofit Version. ( with standard parameter ) |

| 185 | SCHENCK PROCESS | V035374.B02 DISOCONT control unit in field housing VLB 20120-3D, for ATEX zone 22 |

| 186 | SCHENCK PROCESS | D726176.10 Load Cell RTN 10t C5 / C4MI7,5 According to data sheet BV-D2019GB |

| 187 | SCHENCK PROCESS | V096000.B01 DISOMAT Tersus, panel mount unit VEG 20450, in accordance to data sheet BVD 2273 consisting of: 1 measuring circuit VME 0450/ loaded software: VWW 20450 |

| 188 | SCHENCK PROCESS | Speed sensor Oder code: C71800005 |

| 189 | SCHENCK PROCESS | DISOCONT Tersus Type: VCU20103 Mat.-No.: V084273.B01 Software: VCF 20170 |

| 190 | SCHENCK PROCESS | Load cell Part Number: C18305-1 Capacity: 100LBF Option 1 (US Origin) |

| 191 | SCHENCK PROCESS | Load cell Part Number: C18305-1 Capacity: 100LBF Option 2 (China Origin) |

| 192 | SCHENCK PROCESS | V063320.B01 DISOMAT OPUS VEG 20700 maxi panel mount unit Note: Discontinued device series. Please do not use for new plants. Only serves for spare parts supply |

| 193 | SCHENCK PROCESS | V547330.B03 Load cell SB4-20kN-C3 |

| 194 | SCHENCK PROCESS | E056888.04 Load foot to load cell SB4/SF4 5kN/10kN/20kN |

| 195 | SCHENCK PROCESS | E056888.04 Load foot to load cell SB4/SF4 5kN/10kN/20kN |

| 196 | SCHENCK PROCESS | D726176.10 Load Cell RTN 10t C5 / C4MI7,5 According to data sheet BV-D2019GB |

| 197 | SCHENCK PROCESS | V058895.B07 Load cell PWS 500kg/350Ohm 0,05% According to data sheet BV-D2214 |

| 198 | SCHENCK PROCESS | V058895.B06 Load cell PWS 300kg 0,05% data sheet BV-D 2214GB |

| 199 | SCHENCK PROCESS | D726178.04 Load cell RTN 150t 0,05% according to data sheet BV D 2019GB |

| 200 | SCHENCK PROCESS | D724784.04 Load cell RTN 100t 0,05%, according to data sheet BV-D2019GB |

| 201 | SCHENCK PROCESS | D726178.04 Load cell RTN 150t 0,05% according to data sheet BV D 2019GB |

| 202 | SCHENCK PROCESS | D724784.04 Load cell RTN 100t 0,05%, according to data sheet BV-D2019GB |

| 203 | SCHENCK PROCESS | V058895.B04 Load cell PWS 100kg 0,05% data sheet BV-D 2214 |

| 204 | SCHENCK PROCESS | V058895.B04 Load cell PWS 100kg 0,05% data sheet BV-D 2214 |

| 205 | SCHENCK PROCESS | V058895.B04 Load cell PWS 100kg 0,05% data sheet BV-D 2214 (Sales check lai code) |

| 206 | SCHENCK PROCESS | V053953.B01 Cable junction box VKK 28004, for max. 4 load cells, polyester housing, spring terminals |

| 207 | SCHENCK PROCESS | D724781.04 Load cell RTN 22t 0,05% According to data sheet BV-D2019GB |

| 208 | SCHENCK PROCESS | D724781.04 Load cell RTN 22t 0,05% According to data sheet BV-D2019GB |

| 209 | SCHENCK PROCESS | D726178.04 Load cell RTN 150t 0,05% according to data sheet BV D 2019GB |

| 210 | SCHENCK PROCESS | D724784.04 Load cell RTN 100t 0,05%, according to data sheet BV-D2019GB |

| 211 | SCHENCK PROCESS | D726178.04 Load cell RTN 150t 0,05% according to data sheet BV D 2019GB |

| 212 | SCHENCK PROCESS | D726178.04 Load cell RTN 150t 0,05% according to data sheet BV D 2019GB |

| 213 | SCHENCK PROCESS | V063320.B01 DISOMAT OPUS VEG 20700 maxi panel mount unit Note: Discontinued device series. Please do not use for new plants. Only serves for spare parts supply |

TMP là đại diện của Schenck Process tại thị trường Việt Nam, chuyên tư vấn và thực hiện các giải pháp đo lường của hãng Schenck Process cho các ứng dụng công nghiệp như: Thép, Nhiệt điện, Khai thác khoáng sản, thực phẩm, hóa chất...

Hãy liên hệ với chúng tôi để được hỗ trợ !